Manufacturing Monday

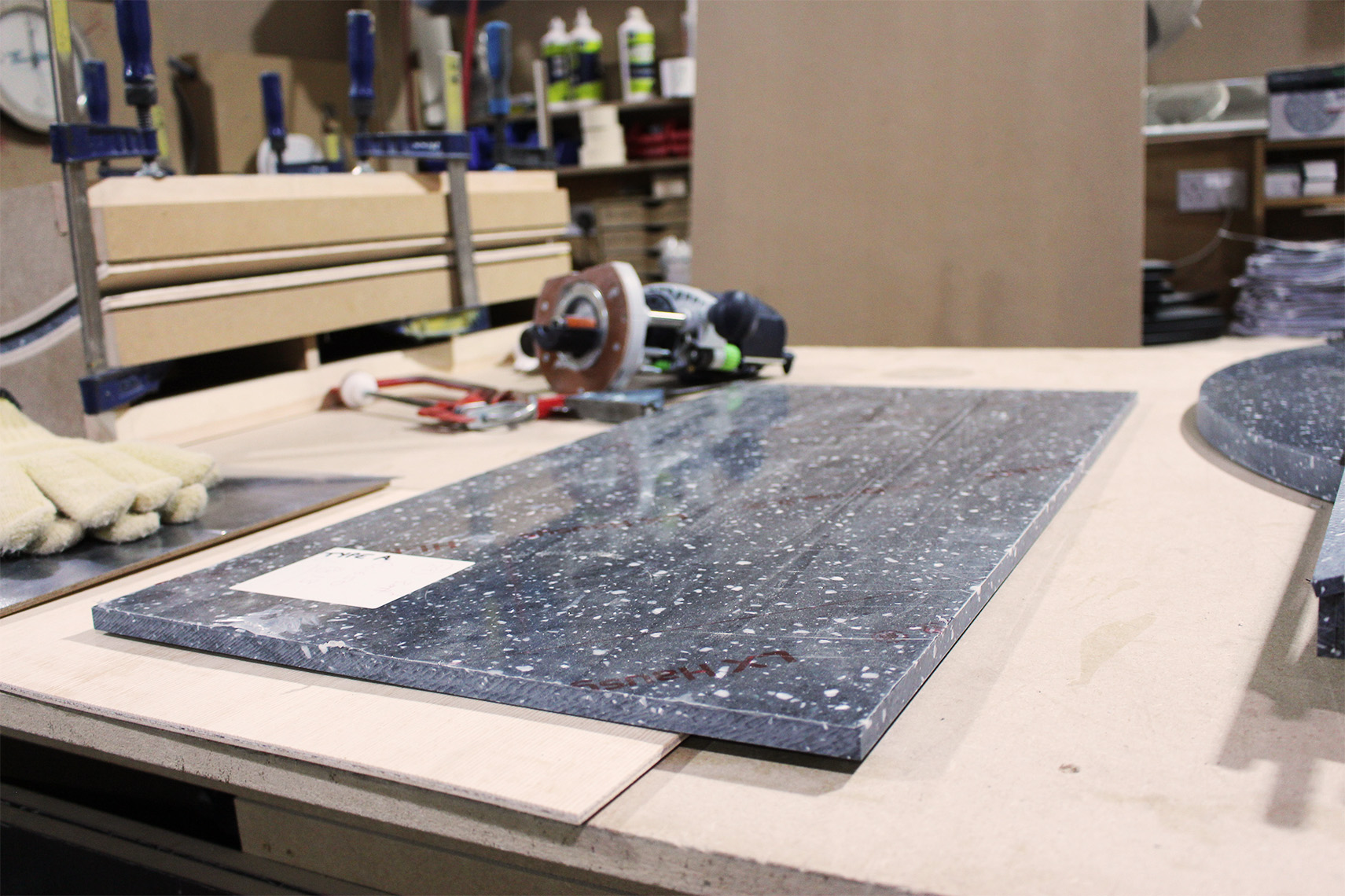

Our expert factory team work with different materials to supply our clients with the best possible pieces to fit their requirements. One such material they use quite often is Corian.

Corian is a thermoformable material meaning it can be shaped into generally any form. Our innovative factory team have repurposed an industrial pizza oven to heat the Corian to 180 degrees; when it becomes pliable.

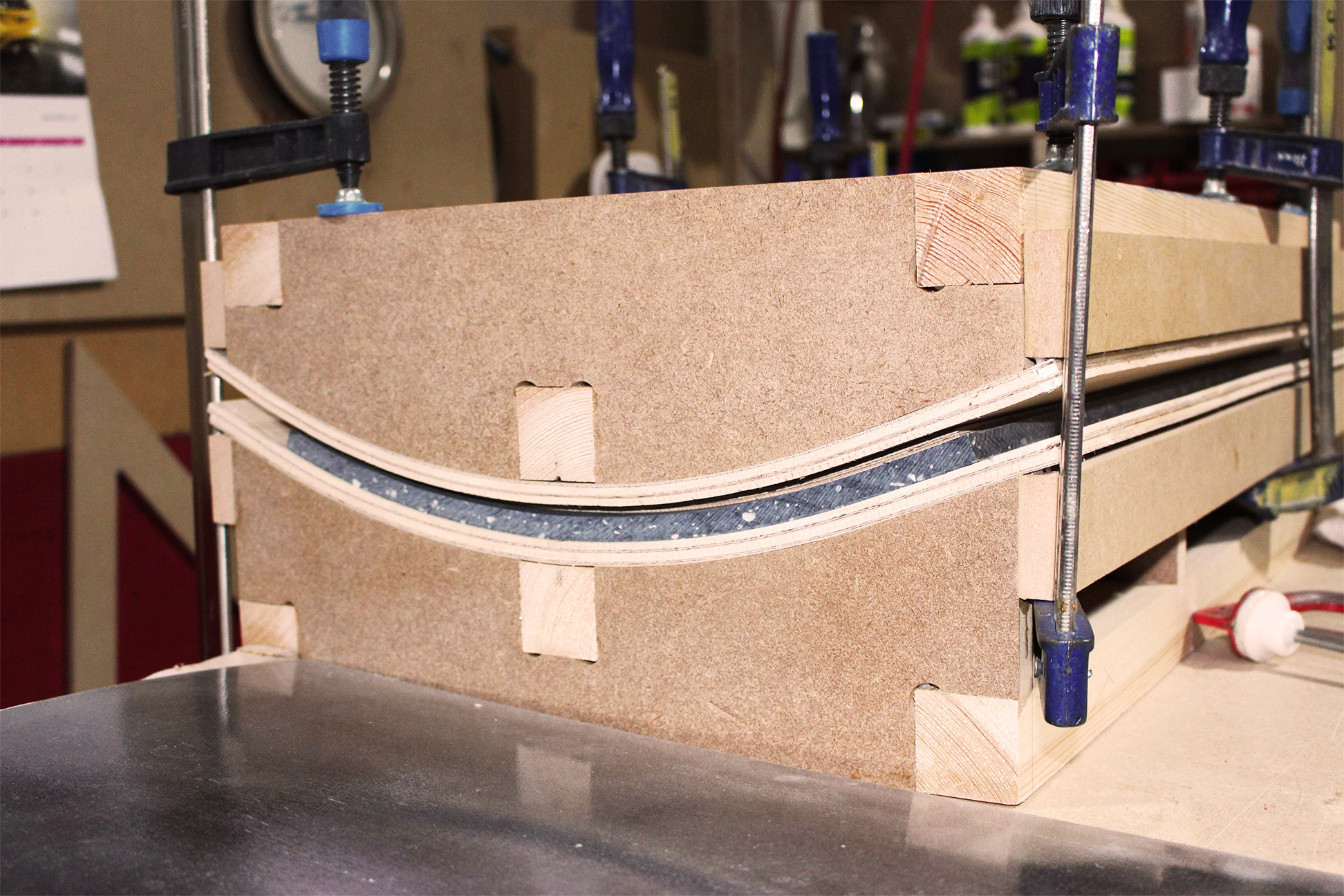

It is then placed into a specifically made cradle and clamped to mould it to the correct shape while it cools. Our team makes each cradle on site to the client’s exact specification; with significant input from our Setting Out department; to ensure the Corian is moulded to the correct shape.

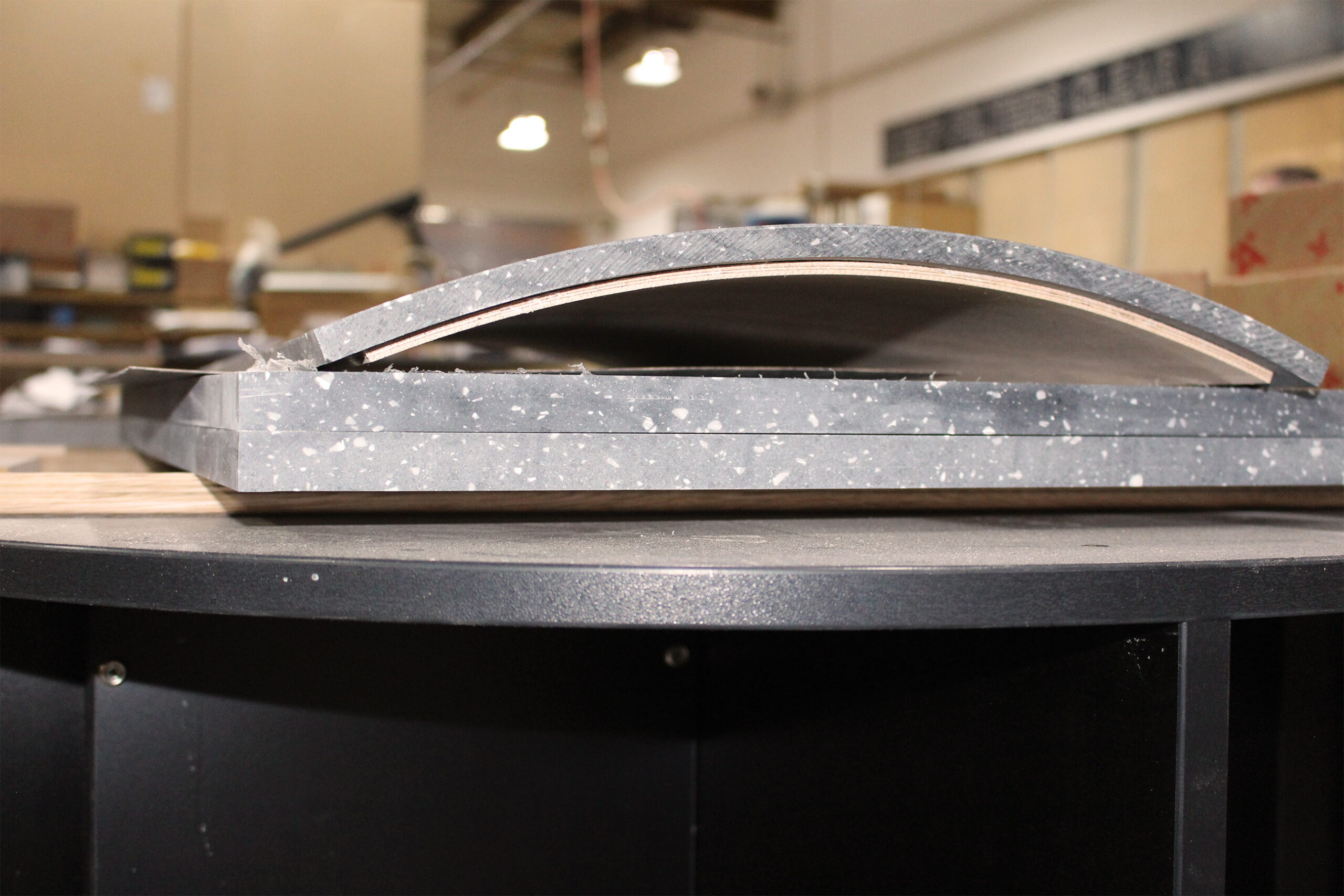

Once completely cooled, the newly moulded piece is removed from the cradle and finished. In the case of the images below, a black laminate sheeting will be applied to the reserve before the curved piece of Corian is installed to the frame.